Cybersecurity For Hydropower Generation

Protecting The Connected Hydropower Plant From Evolving Cyber Threats

Customer/ Partner:

Canadian power generation company.

Customer Requirement:

To comply with NERC-CIP standards and protect critical assets from cyberattacks while protecting operational and business processes efficiency.

Waterfall’s Unidirectional Solution:

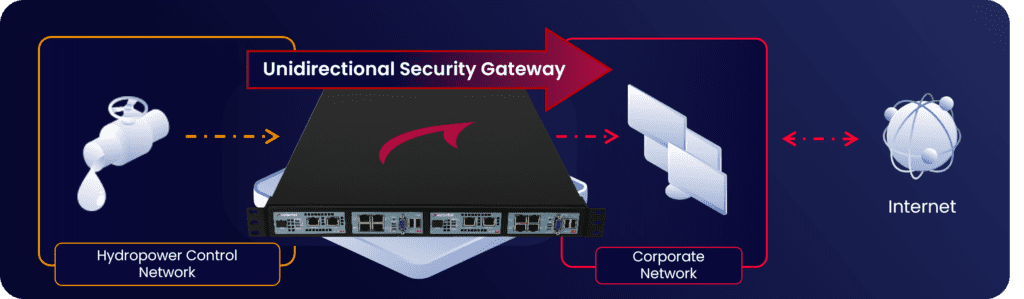

Secure the control system network perimeter from external threats with Unidirectional Security Gateways, and enable Real-Time Enterprise Connectivity & 3rd Party Monitoring creating fully operational OSIsoft PI, GE OSM turbine monitoring, and ICCP server replicas.

The Growing Hydropower Industry And Facing Modern Cyber Threats

With an average growth of 4% per year, hydropower has become the leading renewable source for electricity generation – globally supplying 71% of all renewable electricity. Today, hydropower offers not only clean energy but its infrastructure is also used for freshwater management, such as water supply, and flood management. The importance of hydropower has increased significantly in the past decade, leading to the adoption of innovative technology, advanced control systems, and stronger equipment.

When malicious attackers gain access to an industrial control system they are able to sabotage industrial control and safety processes, leading to costly outages, damaged turbines, threats to personnel safety and even environmental disasters. This is why NERC CIP and other industrial security regulations urge operators to thoroughly secure IT/OT interconnections in order to protect these highrisk access points against cyber terrorism and other attacks. The question is – how to achieve 100% protection from remote cyber threats?

The challenge

To secure the safe, reliable and continuous operation of hydropower control and safety networks from threats emanating from less trusted external networks, yet still provide real-time access to operations data to enterprise users and applications, as well as to turbine vendors and other third parties. The control systems in modern plants are responsible for power generation and water supply which ultimately affect the lives of millions of people. Protecting these critical assets with software (firewalls or other IT security measures) is not enough as all software by nature can be compromised.

Waterfall solution

A Waterfall Unidirectional Gateway was installed between the industrial control system network and the enterprise network. Unidirectional Gateway software connectors replicate OSISoft PI, GE OSM, and ICCP servers from the control network to the enterprise network where enterprise clients can interact normally and bi-directionally with the replicas. A file server replication connector was also deployed, to eliminate the routine use of USB drives and other removable media. Enterprise users and applications, as well as vendors and NERC Balancing Authorities interact bi-directionally with replica servers, while the Unidirectional Gateway hardware physically prevents any Internet-based attack from reaching protected control networks.

Results & benefits

100% Security: The industrial network is now physically protected from threats emanating from external, less-trusted networks.

100% Visibility: The enterprise network continues to operate as if nothing has changed. Instead of accessing servers on the critical operational network, users on the external network now access real-time data from replicated servers for all informational and analytical requirements.

100% Compliance: Unidirectional Gateways are recognized by the NERC CIP standards, as well as other North American and global industrial cyber security standards and regulations.

Theory of Operation

Waterfall Unidirectional Security Gateways replace firewalls in industrial network environments, providing absolute protection to control systems and industrial control networks from attacks emanating from external less-trusted networks. Unidirectional Gateways contain both hardware and software components. The hardware components include a TX Module, containing a fiber-optic transmitter/ laser, and an RX Module, containing an optical receiver, but no laser. The gateway hardware can transmit information from an industrial network to an external network, but is physically incapable of propagating any virus, DOS attack, human error or any cyber attack at all back into the protected industrial network. The Gateways enable vendor monitoring, industrial cloud services, and visibility into operations for modern enterprises and customers. Unidirectional Gateways replicate servers, emulate industrial devices and translate industrial data to cloud formats. As a result, Unidirectional Gateway technology represents a plug-and-play replacement for firewalls, without the vulnerabilities and maintenance issues that accompany firewall deployments.

Unidirectional Security Gateways Benefits:

![]() Safe integration of hydropower safety & control systems with external networks

Safe integration of hydropower safety & control systems with external networks

![]() Safe, continuous monitoring of critical systems

Safe, continuous monitoring of critical systems

![]() Compliance with industrial cyber-security regulations, standards and best-practice guidance, including NERC CIP

Compliance with industrial cyber-security regulations, standards and best-practice guidance, including NERC CIP

![]() Safe cloud vendor/services supply chain integration

Safe cloud vendor/services supply chain integration

![]() Replacing at least one of the layers of firewalls in a defense-indepth architecture with Unidirectional Gateways breaks the chain of malware infection and prevents pivoting attacks from less-trusted IT networks

Replacing at least one of the layers of firewalls in a defense-indepth architecture with Unidirectional Gateways breaks the chain of malware infection and prevents pivoting attacks from less-trusted IT networks

Global Cybersecurity Standards Recommend Unidirectional Security Gateways

Waterfall Security is the market leader in Unidirectional Gateway technology with installations at critical infrastructure sites across the globe. The enhanced level of protection provided by Waterfall’s Unidirectional Security Gateway technology is recognized as best practice by many leading industry standards bodies, including NIST, ANSSI, NERC CIP, the ISA, the US DHS, ENISA and many more.

Share

Trending posts

Stay up to date

Subscribe to our blog and receive insights straight to your inbox