Securing Pharmaceutical Manufacturing Systems and Intellectual Property

Building Pharmaceutical’s Immunity Against Intellectual Property Theft

Customer/ Partner:

European pharmaceutical manufacturer.

Customer Requirement:

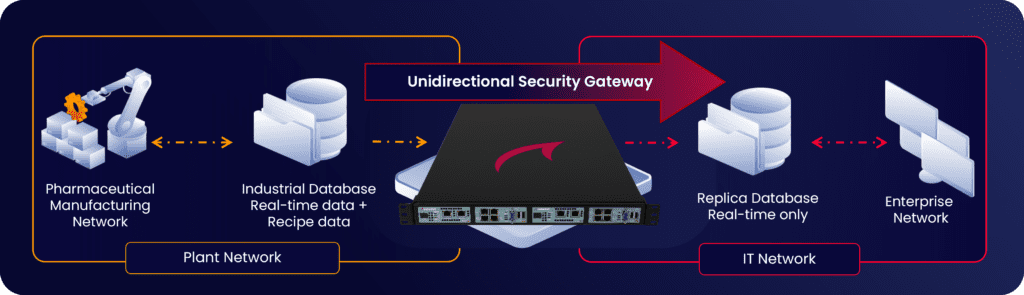

To provide enterprise-wide access to real-time data while protecting manufacturing operations and product recipes from cyber attacks.

Waterfall’s Unidirectional Solution:

Deploy Unidirectional Security Gateways as safe network integration between manufacturing systems and IT systems, enabling real-time, enterprise-wide monitoring of operations while preventing remote access to product recipes in manufacturing control systems

Cyber Risks To Pharmaceutical Manufacturing

Manufacturing network digitization is either underway or in the planning phase at most pharmaceutical manufacturing facilities. The benefits of enterprise-wide access to real-time data from industrial control systems are undeniable, but the risks are considerable as well. Modern cyber attacks can breach firewalls and other software security systems to steal product recipes and other vital intellectual property and threaten to interfere with industrial control operations as well.

The challenge

To secure the production network from intellectual property (IP) theft and cyber-sabotage from threats emanating from less trusted external networks, yet still provide safe, real-time access to live operations data for the corporate network. Modern industrial attacks routinely defeat firewalls, encryption, anti-virus systems, security updates, intrusion detection systems and other software protections. Protecting pharmaceutical critical assets with firewalls and other software security measures is not enough.

Waterfall solution

A Waterfall Unidirectional Gateway was installed to replicate the control system historian database to an enterprise historian. Unidirectional Gateway hardware makes online attacks on ICS networks from external networks physically impossible. To protect product recipes and other trade secrets, the Unidirectional Gateway was configured to replicate only those historian tags that are safe to share with the enterprise network. Tags containing recipes, formulas and other intellectual property were left untouched in the control system historian.

Results & benefits

- 100% Security: Production processes and intellectual property are now physically protected from any attacks originating on external networks.

- 100% Visibility: Enterprise users and applications have access to all permitted real-time data via the enterprise historian.

- 100% Compliance: Unidirectional Gateways simplify compliance with global regulations, standards and best practice guidance for industrial cybersecurity.

Theory of Operation

Waterfall Unidirectional Security Gateways replace firewalls in pharmaceutical manufacturing network environments, providing absolute protection to manufacturing control systems from attacks emanating from external networks. Unidirectional Gateways contain both hardware and software components. The hardware components include a TX Module, containing a fiber-optic transmitter/laser, and an RX Module, containing an optical receiver, but no laser. The gateway hardware can transmit information from the manufacturing network to the external network, but is physically incapable of propagating any virus, DOS attack, human error or any cyber attack at all back into the protected network. The Gateways enable vendor monitoring, industrial cloud services, and visibility into operations for modern enterprises and manufacturers. Unidirectional Gateways replicate entire servers or selected subsets, emulate industrial devices and translate manufacturing data to cloud formats. As a result, Unidirectional Gateway technology represents a plug-and-play replacement for firewalls, without the vulnerabilities and maintenance issues that accompany firewall deployments.

Unidirectional Security Gateways Benefits

![]() Ultimate protection from remote attack consequences, including IP theft, damage to devices and manufacturing process disruption.

Ultimate protection from remote attack consequences, including IP theft, damage to devices and manufacturing process disruption.

![]() Smart devices and control systems are securely integrated with external networks.

Smart devices and control systems are securely integrated with external networks.

![]() Simplifies audits, change reviews, and security system documentation.

Simplifies audits, change reviews, and security system documentation.

![]() Prevents all remote access to production recipes stored in manufacturing control systems.

Prevents all remote access to production recipes stored in manufacturing control systems.

![]() Replaces at least one layer of firewalls in a defense-in-depth architecture, breaking the chain of infection and pivoting attacks.

Replaces at least one layer of firewalls in a defense-in-depth architecture, breaking the chain of infection and pivoting attacks.

Security And Compliance

• Certification: Common Criteria EAL 4+, ANSSI CSPN, NITES Singapore, CCC China

• Assessments: US DHS SCADA Security Test Bed & Japanese Control Systems Security Center Bed, Idaho National Labs, Digital

Bond Labs, GE Bently Nevada Systems Labs, and NISA Israel

• Complies with: Global ICS Standards & Regulations, including NERC CIP, IEC 62443, NRC 5.71, NIST 800-82r2, CFATS, ISO, IIC SF,

ANSSI, and many more

Share

Trending posts

Applying the New NCSC / CISA Guidance

IT/OT Cyber Theory: Espionage vs. Sabotage

Ships Re-Routed, Ships Run Aground

Stay up to date

Subscribe to our blog and receive insights straight to your inbox